Cloud and API-based 3D engineering platform provider Metafold has announced new features aimed at promoting wider acceptance of 3D printing and lightweighting as alternatives to conventional manufacturing methods.

The update incorporates compression simulation, conformal mapping for lattice structures, and substantial alterations to both the user interface (UI) and API. These changes aim to improve accessibility for engineers and software developers involved in additive manufacturing design. Additional features comprise template workflows, extended support for import and export file formats, improved project management capabilities for teams, and a revamp of the software architecture to expedite releases of new features in the future.

“Additive manufacturing shouldn’t be so hard, yet the mind-boggling geometric complexities have prevented companies from adopting advanced 3D printing capabilities,” shared Dr. Elissa Ross, Co-Founder and CEO of Metafold. “With our new release, we’re trying to help more companies see all the benefits of additive manufacturing by making our breakthrough geometry kernel accessible to more engineers and more software developers. They can create new shoes, explore biotech developments, or make heat exchange advancements and other innovations while leaving the mathematical intricacies to Metafold.”

Simplifying additive manufacturing

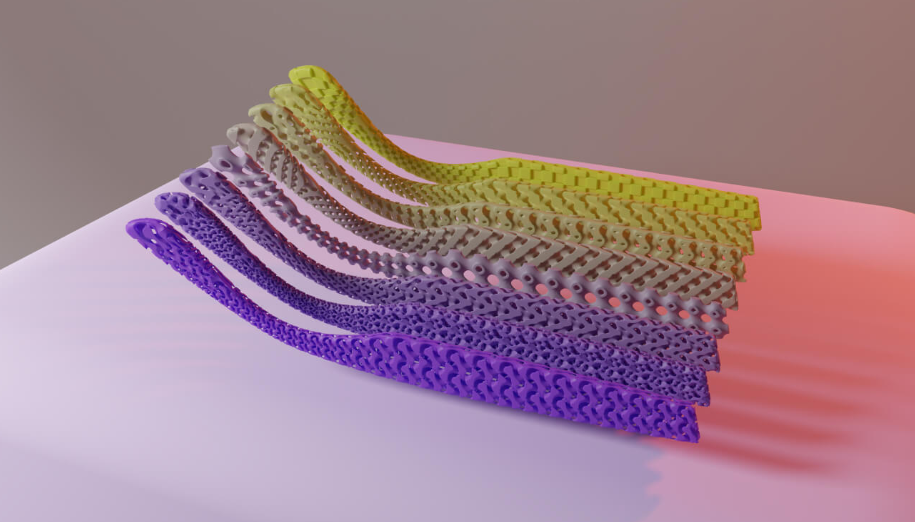

A significant addition is the introduction of one-click simulation for 3D engineered parts, ensuring high precision in predictive performance for mechanical compression. This simulation allows engineers to quickly assess and finalize designs without relying on physical test prints or external simulation applications. Conformal mapping, seamlessly integrated into Metafold, streamlines mapping lattice cells to a part boundary. By allowing engineers to concentrate on product design, this integration ensures that Metafold takes on the task of efficiently resolving complex geometry.

Designers benefit from UI updates, experiencing a more user-friendly work environment that lessens the cognitive load linked to software navigation, thus affording more time for creative ideation. The enhanced API, constructed on contemporary web standards, not only provides more samples but also expands access to next-generation geometry processing capabilities. It holds the potential to accelerate the time it takes for web-based applications with complex geometry to reach the market.

“The Additive industry is at a critical point where design and simulation simply don’t live up to the potential of the technology,” said Jacques Perrault, 3D Design Pioneer and Influencer. “Metafold’s unique approach challenges the status quo, ushering in a new class of additive software built for scale and empowered by the cloud.”

For a limited time, Metafold is offering open beta access to simulation capabilities at three simulations per month in the free edition of the Metafold Platform. Simulation and conformal mapping are expected in the Professional edition in the future. Interested parties can explore the open beta here.

Effortless additive design and simulation

Metal 3D printer developer Meltio launched Meltio Space software and the Meltio Robot Cell, responding to the increasing demand for its Meltio Engine Robot Integration. The Meltio Robot Cell, a turn-key solution for 3D printing metal parts, offers a safer and more efficient method. Meltio Space, a user-friendly toolpath generator, supports various robotic brands, providing planar and nonplanar toolpaths. The software ensures accurate 3D printing by simulating robot movements, minimizing errors. Optimizing the capabilities of the Meltio Engine, Meltio Space delivers continuous updates and provides a user-friendly interface, all at a competitive annual subscription price.

Engineering software developer nTop launched a software update named nTop 4, aiming to address challenges in additive manufacturing (AM) design and production. nTop 4 includes Field Optimization, a generative design technology streamlining AM design by managing complex parameters and enhancing part performance. Implicit Interop eliminates data exchange bottlenecks, reducing file sizes and facilitating seamless data transfer. nTop Automate improves design automation, now available for Linux, enabling cost-effective cloud computing. nTop Accelerate offers personalized training and workshops to maximize impact.

Read all the 3D Printing Industry coverage from Formnext 2023.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows transform complex lattices to perfectly fit part boundary without sacrificing design intent. Photo via Metafold.

منبع: https://3dprintingindustry.com/news/metafold-revolutionizes-additive-manufacturing-with-new-features-for-3d-printing-and-lightweighting-226538/?utm_source=rss&utm_medium=rss&utm_campaign=metafold-revolutionizes-additive-manufacturing-with-new-features-for-3d-printing-and-lightweighting