3D printing has opened up a world of possibilities, but when it comes to printing with clay, there are challenges abound. Enter maker David Sfier, who has developed an updated extruder designed to work with an Ender 3 printer, making clay 3D printing more accessible and practical.

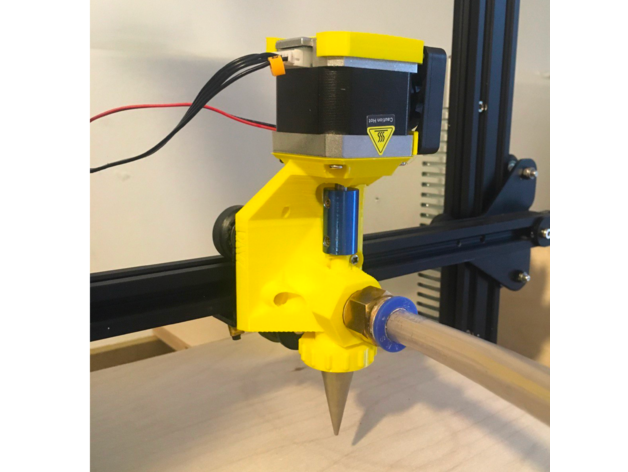

What sets this custom extruder apart is its ability to handle clay, a material that defies traditional spool-based storage. Instead, a clear tube feeds lightly pressurized clay into the extruder. As air escapes from the top, an auger efficiently homogenizes the clay and propels it through the nozzle.

The extruder’s ingenious design tackles the issue of air bubbles (a common problem in clay printing) by allowing air to vent through a narrow gap at the top, the extruder ensures smooth clay flow downward.

Sfier drew inspiration from clay-printing pioneers like Piotr Waśniowski and his de-airing clay extruder, along with Jonathan Keep, whose comprehensive documentation on 3D printing with clay is readily available.

The diversity of challenges in clay printing invites continual innovation, with unconventional methods like using a subwoofer under a print bed leading to unique patterns.

You can learn more about the project, and download the project files over at this link.

Source: hackaday.com

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.

منبع: https://3dprinting.com/news/maker-3d-prints-clay-with-custom-ender-3-extruder/