Register now for our Additive Manufacturing Advantage online event for insights on AM developments in aerospace, space, and defense sectors from industry leaders!

In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features new materials, reseller deals, and software, and Slice Engineering settling a lawsuit against Anker Innovations Technology Co. Ltd.

Read on for the most recent updates from Eplus3D, Roboze, Xact Metal, and more.

Business deals and acquisitions from Eplus3D, Lithoz, AddUp, and more

Starting off this week with business news, Argentina-based orthopedic implant manufacturer BIOPROTECE S.A. has upgraded its metal additive manufacturing (AM) capabilities to meet the growing demand for customized implants by collaborating with Eplus3D. BIOPROTECE S.A. acquired the EP-M260 Metal 3D Printer, leading to a 35% increase in market share.

With a team of 86, including a dedicated 3D printing division, BIOPROTECE S.A. transitioned from traditional CNC machining to 3D printing for improved efficiency and shorter production times. The company now produces 30% of its implants using advanced 3D printing technology, primarily in titanium, and plans further expansion to meet increasing demand and diversify material use.

Following next, 3D printer OEM Snapmaker celebrated its 8th anniversary on June 1st with the theme “Play Well.” The celebration features a 48-hour Makerathon on May 31st and June 1st, where 10 teams will create various items, livestreamed on Facebook. Snapmaker has also introduced the Snapmaker Artisan Premium, a 3-in-1 3D printer with a dual extruder 3D printing module, 40W laser module, 200W CNC module, 400mm3 workspace, and modular design. This system is available for orders from May 28th for $2999 / €3299. Anniversary offers include discounts, referral bonuses, and the Print and Play Challenge video contest running until June 16th.

Additionally, ceramic 3D printing company Lithoz has become a member of the Manufacturing Technology Centre (MTC) to enhance ceramic 3D printing capabilities for industrial users in the UK. Through this collaboration, MTC will expand its additive manufacturing offerings by integrating Lithoz’s CeraFab System S65.

In doing so, MTC engineers will be able to process a variety of high-performance ceramics, thereby improving their ability to design and manufacture intricate ceramic structures. Sherry Ghanizadeh, Senior Research Engineer at MTC, anticipates leveraging Lithoz’s advanced CeraFab system to explore new possibilities in ceramic AM across sectors such as power, energy, and defense.

Metal AM company AddUp has launched LevelUp, a new Service Department aimed at enhancing customer support. This department will offer comprehensive solutions including training, co-design services, qualification support, maintenance, and process optimization. LevelUp’s portfolio includes three main offerings: Additive Journey Kickstart for starting out in additive manufacturing, Industrial Launch Support for scaling capabilities, and Business Growth Partnership for long-term productivity.

Israel-based AM consultancy 3D Alliances has launched The IMPACT Program, which addresses the growth challenges faced by AM companies. It emphasizes optimizing sales via robust channel networks and effective management methodologies. By studying top-performing sales partners, the program extracts best practices to elevate overall network performance.

Startups, scale-ups, and market leaders benefit by accessing new partners, refining sales strategies, and addressing leadership gaps in expansive global networks. Tailored solutions cater to each company’s growth stage and challenges, aiming to maximize revenue potential and strategic momentum.

In another news, CORE Industrial Partners’ portfolio company PrecisionX Group, has acquired National Manufacturing Co. Founded in 1944 and based in Piscataway, New Jersey, National Manufacturing specializes in precision deep and shallow drawn stamping, CNC milling, and various value-added services.

The company serves aerospace, defense, electronics, and medical sectors, handling complex materials such as Inconel and titanium. National Manufacturing holds ISO13485, AS9100, and ISO9001 certifications, ensuring high-quality production of critical components for medical implants and other industries.

New materials from AM 4 AM, Nanoscribe, and more

Next in line are novel materials, Luxembourg-based materials company AM 4 AM has achieved enhanced mechanical properties of its HiperAL aluminum alloy for additive manufacturing.

Through patented cold plasma treatment, HiperAL, a zirconium derivative of the 7000 series, now offers impressive mechanical properties: 525 MPa in yield strength and 550 MPa in ultimate tensile strength (UTS). Developed in collaboration with partner Pint, this material excels in performance, making it suitable for demanding AM applications. HiperAL promises substantial weight reduction, cost-effectiveness, and reliable production, solidifying its position in the additive manufacturing sector.

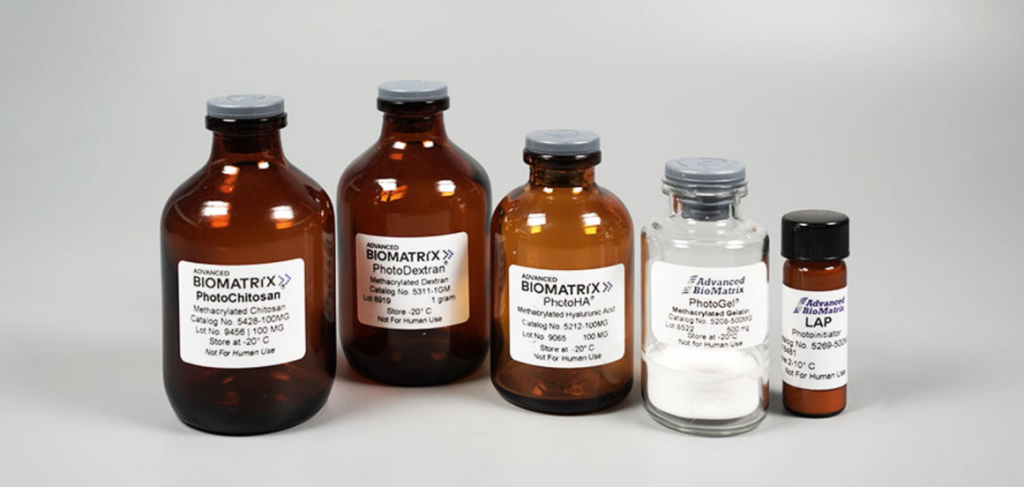

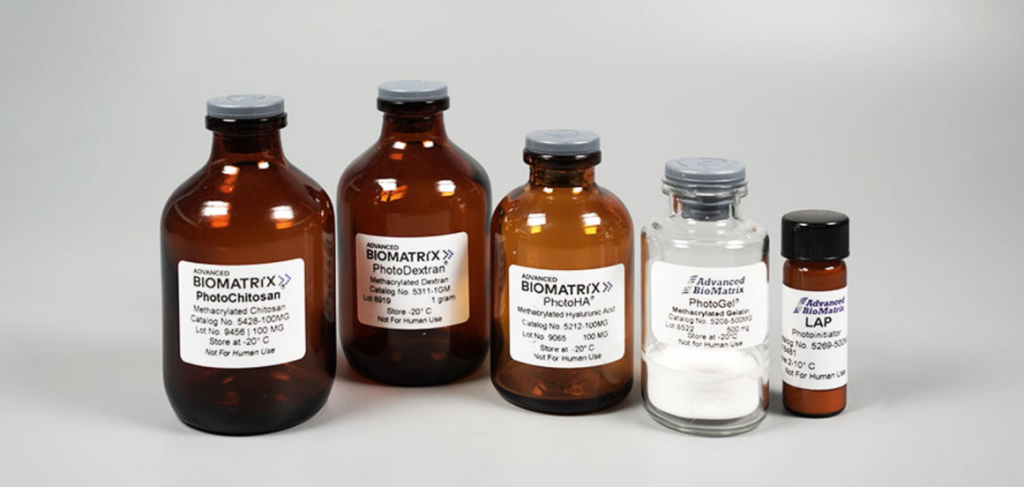

Two-Photon Polymerization (2PP) 3D printer manufacturer Nanoscribe and Advanced BioMatrix have partnered to introduce four specialized bioresins for Two-Photon Polymerization (2PP) 3D printing, aimed at advancing bioprinting capabilities.

Leveraging Nanoscribe’s precision printing expertise and Advanced BioMatrix’s biomaterial development, these bioresins named PhotoGel (methacrylated gelatin), PhotoHA-Stiff (methacrylated hyaluronic acid), PhotoDextran (methacrylated dextran), and PhotoChitosan (methacrylated chitosan) offer exceptional precision and versatility. They cater to diverse applications in high-resolution 3D bioprinting, such as tissue engineering and drug delivery.

Digital manufacturing service provider Protolabs has launched PA 12 Glass Beads Smooth Grey for its Multi Jet Fusion 3D printing process, offering enhanced heat resistance, dimensional stability, and long-term wear resistance.

This 40% glass bead polyamide is ideal for producing small series and prototypes, expanding applications across various industries. The material’s superior thermal properties make it suitable for environments with high heat, like engine cooling systems, while maintaining tolerances of +/- 0.25mm to 0.002 mm/mm.

Novel software from Carbon, MakerVerse, and more

Moving on to software, US 3D printer OEM Carbon has introduced AO Stack, a new software tool for its M2 and M3 printers, as part of its Automatic Operation suite. AO Stack enables dental labs to print multiple DPR10 models in one unattended run, increasing model output by up to three times. It integrates into daily operations with support from Carbon Academy. Available starting May 17, 2024, AO Stack requires software version 1.41 or above and can be accessed by contacting (email protected).

“The introduction of AO Stack is a milestone in our ongoing quest to innovate and provide transformative solutions to our customers,” said Brice Harkey, Senior Product Manager of Oral Health at Carbon. “By allowing up to three builds worth of models on a single unattended print, AO Stack offers the opportunity for an increase in overnight production capabilities without additional hardware or oversight.”

3D printing software developer Dyndrite has introduced support for HP’s Multi-jet Fusion (MJF) and Metal Jet 3D printers with its new print preparation software. This software offers features like automated build preparation from large mesh files or native CAD, advanced 2D and 3D labeling, and fast nesting operations. Built on the Accelerated Computation Engine (ACE), it improves production speed, repeatability, and traceability. HP 3D printer users can join the Early Adopter Program for early access and testing of the software.

Berlin-based industrial parts sourcing platform MakerVerse has introduced its Technology and Material Advisor, a new digital tool aimed at helping users select optimal Additive Manufacturing technologies and materials based on project requirements. Offering choices across more than twenty properties such as high resolution and heat resistance, designers can easily find suitable materials for both metals and polymers.

The advisor includes detailed data sheets for nearly forty materials, facilitating informed decision-making. MakerVerse supports a diverse supply chain encompassing CNC machining, injection molding, and various Additive Manufacturing methods, complemented by comprehensive engineering services for seamless production support.

Elsewhere, AdditiveLab and AddUp have collaborated on AddUp Manager 7.6, an advanced build preparation software for metal AM. This updated version includes a dedicated simulation engine designed for the FormUp 350 Powder Bed Fusion machine, enhancing accuracy by predicting stresses and deformations before printing.

Known for its extensive capabilities, AddUp Manager enables users to fine-tune more than 250 variables, customize melting strategies, and visualize laser trajectories. By integrating simulation directly into the software, the update aims to streamline workflows, reduce costs associated with separate tools, and elevate the efficiency and success rates of metal 3D printing processes.

Innovative 3D printing applications

Fashion tech designer Laura Civetti, in collaboration with Juanda Cabrera, has created Trinity, a pioneering bio 3D printed dress that demonstrates the potential of bio-based materials in the fashion industry. Trinity integrates material properties and human body requirements through computational design, resulting in a versatile material surface.

Utilizing additive manufacturing techniques, the dress ensures precise material deposition, thereby enhancing durability and biodegradability over extended use. This innovation addresses challenges in material properties and manufacturing complexity, showcasing Civetti and Cabrera’s expertise in merging computational design with additive manufacturing to advance sustainable fashion technology.

Architecture and design studio IOUS Studio collaborated with WASP to create Fusion, a 3D printed ceramic wall cladding showcased at SaloneSatellite during Milan Design Week. Hosted at WASP headquarters through its Residency program, IOUS Studio utilized the WASP 40100 Production system for rapid and customized ceramic production.

Inspired by the sea, Fusion’s design captures dynamic light effects on water surfaces through parametric and computational design. Additionally, WASP’s Residency program now offers architects, designers, and researchers access to its 3D printing technologies, fostering innovation in sustainable materials and enhancing cultural contributions in various fields.

Incredible 3D achieves 3,000 3D printed implants milestone

As of April 2024, Incredible 3D has surpassed 3,000 successful 3D printed implants, establishing itself as an “industry leader in India and Southeast Asia.” Its Pune facility meets Indian FDA standards, employing advanced technology and ISO-certified methods. Specializing in cranial, maxillofacial, and orthopedic implants, the company has collaborated with nearly 1,000 surgeons and maintains over 2,000 connections nationwide. Utilizing biocompatible materials and rigorous quality control, Incredible 3D is dedicated to enhancing patient recovery and rehabilitation.

NIAR receives $10M funding from NASA for hypersonic materials research

Wichita State University’s National Institute for Aviation Research (NIAR) is set to receive over $10 million from NASA to develop advanced materials for hypersonic applications. This funding will enable research into high-temperature materials for use in hot structures and thermal protection systems for hypersonic vehicles. This program aims to address technological gaps, focusing on materials that can endure extreme temperatures and extended flights. The research involves automated fabrication, characterization, and testing of refractory materials, and will enhance the capabilities of the National Defense Prototype Center. Senator Jerry Moran secured this funding from NASA on behalf of Wichita State.

“Our collaboration with NASA Aeronautics will continue to advance through the Hypersonics Technology Project, focusing on sustaining hypersonic competency for national needs while advancing applied hypersonic research,” said John Tomblin, WSU senior vice president for Industry and Defense Programs and NIAR executive director. “We are fortunate to have the unwavering support of Senator Moran to expand this collaboration with NASA and key representatives in the industry.”

amsight wins Digital Innovation Startup Competition

AM data management and analytics software provide amsight won the Digital Innovation Startup Competition organized by Germany’s Federal Ministry for Economic Affairs and Climate Action (BMWK). This competition, recognizing innovative digital business startups since 1997, awarded amsight €7,000 and a coaching budget. The jury was impressed by amsight’s data-driven software, which creates a full digital twin of the AM process chain and optimizes costs, quality, and resource efficiency.

DyeMansion launches Global Black Diamond Finishing Hub for rapid 3D printing solution

Germany-HQ’d automated post-processing provider DyeMansion has introduced the Black Diamond Finishing Hub. This new global online platform offers Vapor Smoothing, Blasting, and Black Coloring services for PA11 and PA12 materials from any powder bed 3D printer, with a quick turnaround of 2 working days and no minimum order requirements.

It complements DyeMansion’s existing hardware and On-Demand Finishing services, which have been foundational since the company’s inception. Initially launched from Munich and Austin, the hub will expand worldwide through DyeMansion’s global production partner network by year-end. Partners can integrate from launch, facilitating distribution and registration as finishing partners to establish their own hubs via the platform.

Slice Engineering resolves patent dispute with Anker Innovations Technology

Slice Engineering has settled a patent dispute with Anker Innovations Technology (Changsha, China), concerning Slice’s Adaptable High-Performance Extrusion Head for Fused Filament Fabrication Systems. The settlement addresses allegations that Anker’s AnkerMake M5C 3D printer and hotend infringed U.S. Patent 11,660,810. Initially, Anker contested the patent’s validity and denied infringement. Slice Engineering, known for its advanced industrial 3D printer components, serves a global customer base across various industries.

“We are pleased that Anker changed course and decided to do the right thing after we accused them of infringing one of Slice’s utility patents,” said Dan Barousse, Co-founder and CEO of Slice Engineering. “We believe the strength of our patent portfolio helped promptly facilitate a settlement, allowing us to focus on our core business and customers.”

Xact Metal and 3Dees Industries to expand metal AM in Central Europe

Powder bed fusion 3D printer manufacturer Xact Metal has partnered with 3Dees Industries to expand access to its metal 3D printing solutions in Czechia, Slovakia, and Ukraine. This collaboration aims to enhance accessibility and affordability of metal additive manufacturing in these regions, catering especially to small-to-medium size companies.

The XM200G printer, known for its versatility and compact design, will play a central role, offering precise components crucial for industries like automotive, aerospace, defense, and healthcare. By introducing laser powder-bed fusion technology, the partnership enables the cost-effective production of complex geometries and smooth surface finishes across a range of materials, bolstering industrial capabilities and precision.

Daniel Adam, CEO at 3Dees Industries, added, “Our new partnership with Xact Metal takes us to the next level in 3D printing. Their technology allows us to offer customers solutions that are faster, more accurate, and above all, more economically accessible.”

Envision Racing chooses Roboze for advanced 3D printing solutions in Formula E

Envision Racing in Formula E has selected Roboze to optimize component production with advanced materials through 3D printing solutions. This strategic partnership aims to enhance performance by leveraging Roboze’s expertise in high-precision additive manufacturing.

Utilizing materials such as Carbon PA PRO and Carbon PEEK, known for their lightweight properties and durability, Envision Racing aims to reduce manufacturing errors, improve efficiency, and advance sustainability efforts in the fully electric World Championship racing series. Roboze’s technology not only supports weight reduction initiatives but also contributes to minimizing waste, aligning with Envision Racing’s commitment to environmental responsibility amidst the Race Against Climate Change, says the company.

Frankfurt announces Formnext Chicago 2025, expanding AM trade fair to the US market

In alliance with AMT and Gardner Business Media, Mesago Messe Frankfurt is launching Formnext Chicago, adapting its successful Formnext trade fair concept to the USA, the largest AM market. Scheduled for 8-10 April 2025, Formnext Chicago aims to showcase the complete industrial process chain for AM.

Vice President Sascha F. Wenzler emphasizes the event’s focus on introducing AM to new US companies and industries, highlighting its benefits and fostering business connections. This expansion builds on Mesago Messe Frankfurt’s strategy of tailored AM events globally, including Formnext + PM South China and Formnext Forum Tokyo.

Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows the amsight team being awarded €7,000 and a coaching budget. Photo via amsight.

منبع: https://3dprintingindustry.com/news/sliced-latest-news-from-the-3d-printing-industry-3-230861/?utm_source=rss&utm_medium=rss&utm_campaign=sliced-latest-news-from-the-3d-printing-industry-3