Our review of the Bambu Lab mini A1 concludes with software, print results and final thoughts.

This is part four of a four part series, please read parts one, two and three.

Bambu Lab A1 mini Software

There are two software resources for the A1 mini: BambuStudio, a desktop app, and Bambu Handy, their mobile smartphone app.

BambuStudio is a fork of PrusaSlicer, so it has a ton of terrific features. Bambu Lab has reorganized the interface somewhat, so those familiar with PrusaSlicer will have to find their way around again.

One of the main features is the ability to connect directly to the machine and the cloud, and that’s something I used constantly. You can use the A1 mini in offline disconnected mode, but it is just so convenient to be online.

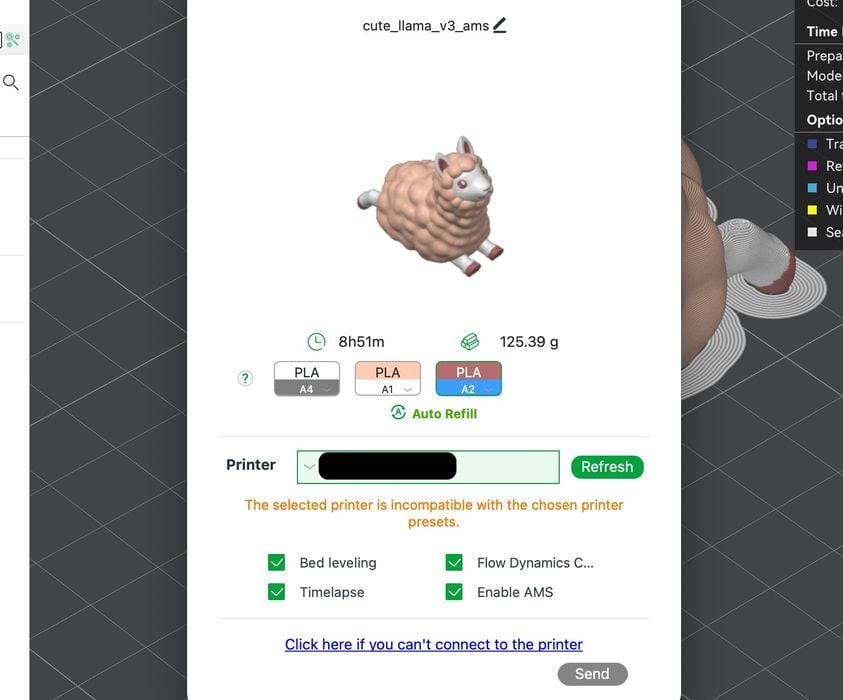

It is possible to download a ton of pre-sliced 3D models from Bambu Lab’s MakerWorld for direct printing, but I did find one issue.

It seems that many of the pre-made jobs are not compatible with the A1 mini, as they were sliced for other Bambu Lab equipment. You have to be careful because the software lets you bring these down and begin working with them before the error appears. Just double check that the file is for the A1 mini before downloading.

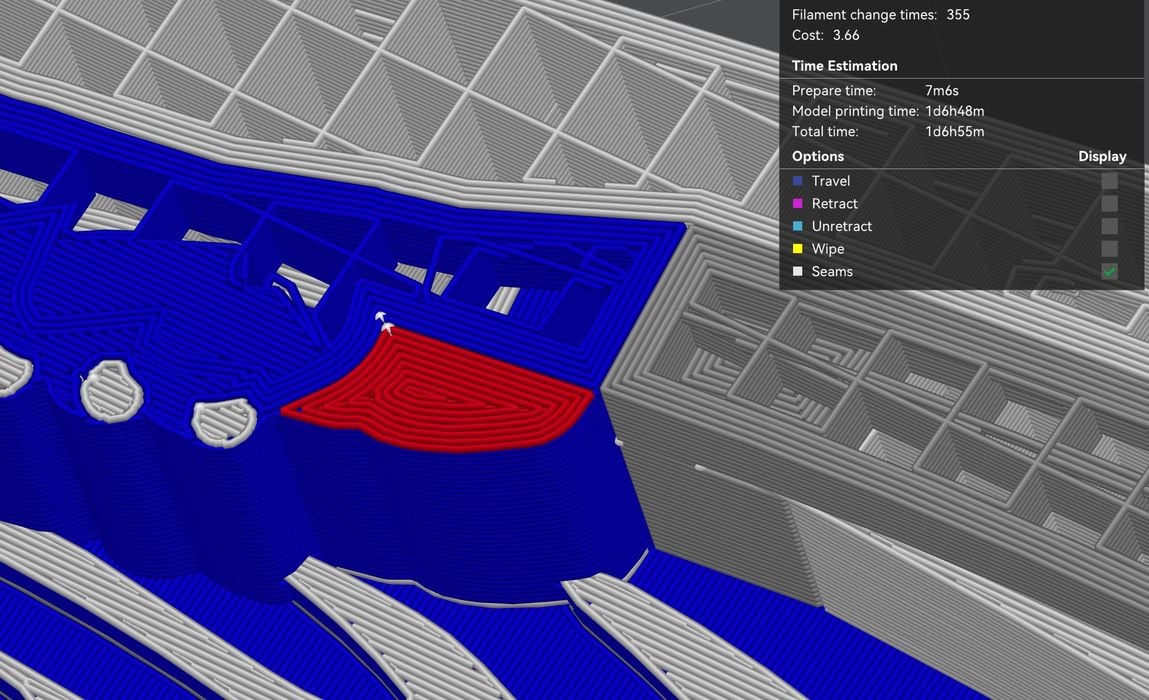

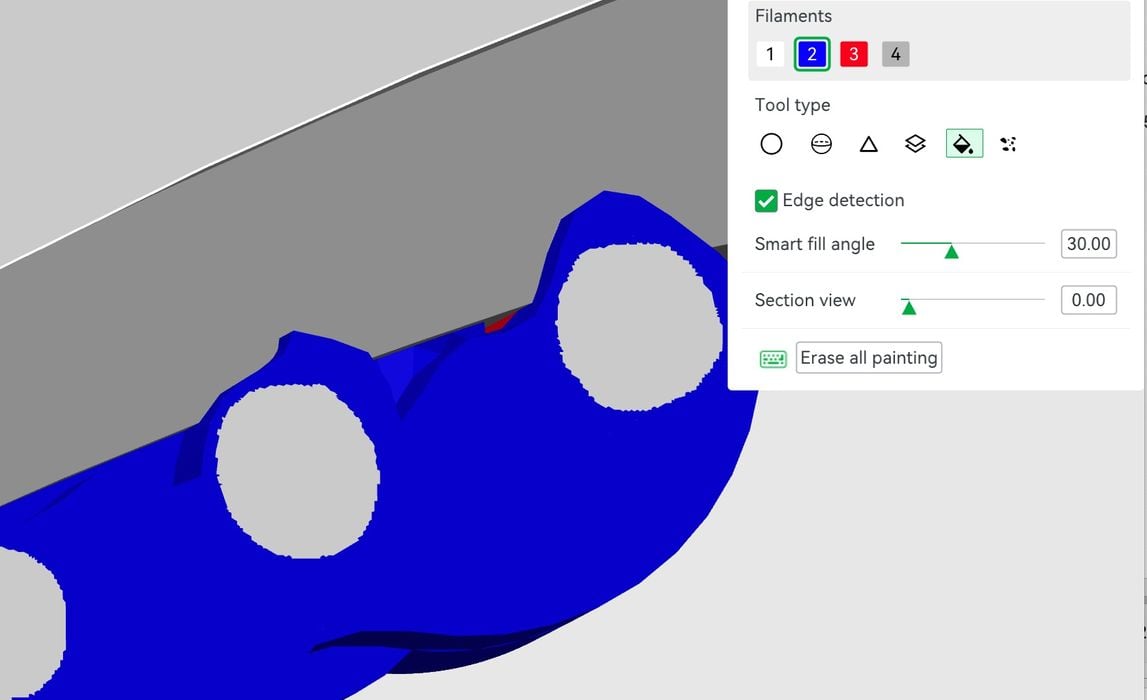

The AMS allows use of multiple colors, and one of the best ways to do so is by using the painting capabilities in bambuStudio. Here you can see how I painted some areas blue in a 3D model. You can now understand why it’s important to ensure your filaments and colors are matched through the system. If not, your visualization will have the wrong colors.

The painting process is pretty good, as there are several tools to use, like freehand, paint a contiguous surface, etc. However, you must have a steady hand, and use the undo button frequently.

I did find that the painting affected not only the surface of the model, but sometimes deep inside. I would be puzzled sometimes by watching material be colored inside the prints where it really didn’t have to be. Nevertheless, the final prints always had the correct surface colors.

One very interesting feature was found when printing the Marble Run mystery box parts. There were so many parts to print that multiple jobs were required. The MakerWorld entry had eleven pre-made “print plates” with these parts ready to go, and you need only print them in order.

What was fascinating was the Bambu Handy app would lead you through from one plate to another as you completed them, with no need to go searching for the next plate.

There’s a ton more that can be said about the software and MakerWorld, but that’s for another day. For now, I’d say the software experience is very good, and the tools are quite powerful.

Bambu Lab A1 mini Print Results

The print results were outstanding, with almost no flaws on any print. In fact, the machine failed only when I screwed up the parameters or the filament broke. There were essentially no errors from the A1 mini.

The #3DBenchy above came out very well and with extreme speed. This job completed in only 17 minutes, far faster than most “high speed” desktop 3D printers.

I tried color layers, and this worked quite well, and there was minimal poop as there were few filament swaps.

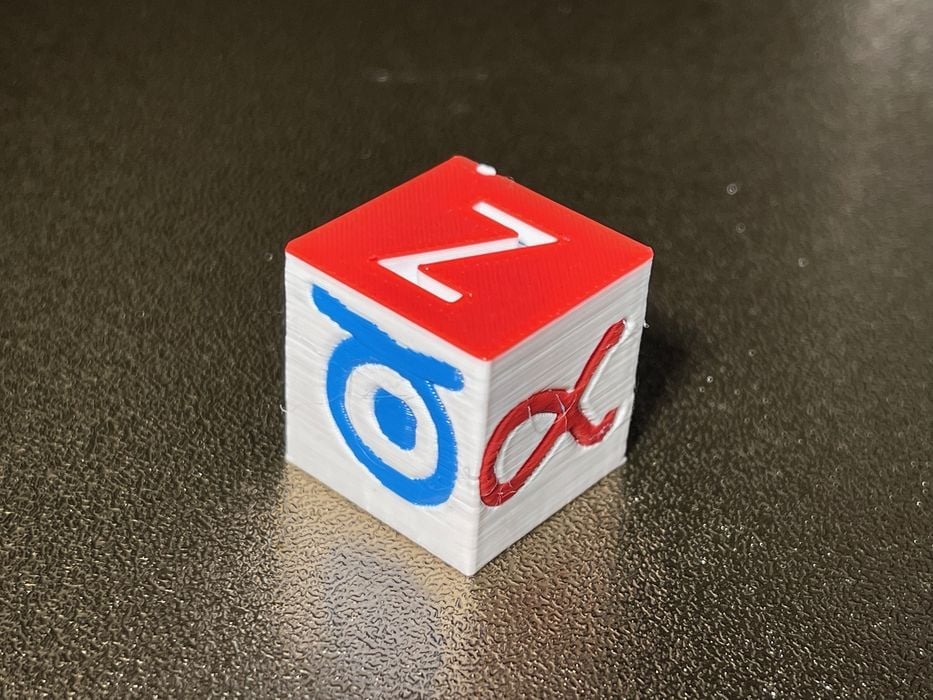

Here I hand-painted some marks on a cube, and they came out quite well.

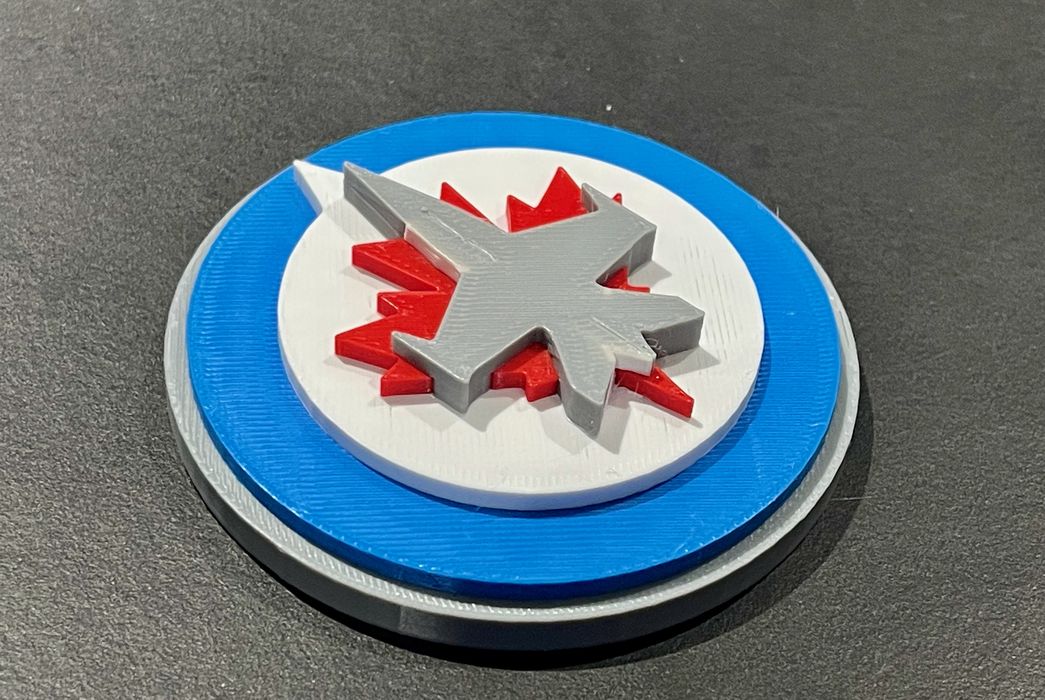

I tried printing a sports logo by coloring the 3D model. This was quite straightforward to do, and the print worked perfectly. You just have to have the right colors on hand, and hopefully you need four or less due to AMS capacity.

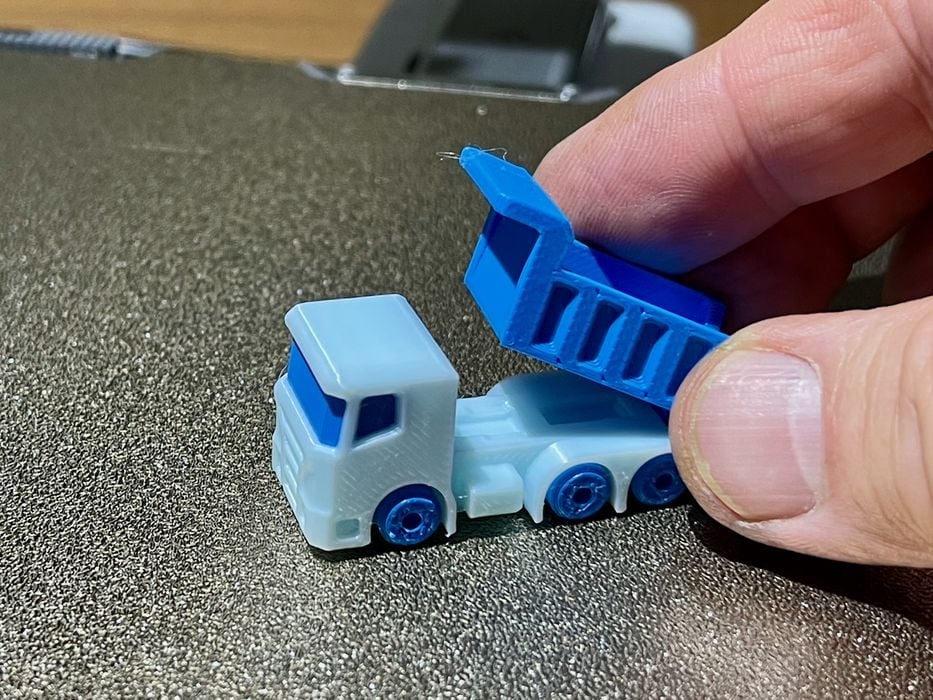

This is a print-in-place truck, which printed perfectly, and was totally articulated afterwards. The dump and wheels worked instantly without any problems. Very impressive!

I tried coloring this 3D model of the famous Japanese wave painting, and it was an incredible result. The job took 13 hours to complete, with countless filament swaps. Not a single problem occurred during the print, and after that I trusted the A1 mini completely.

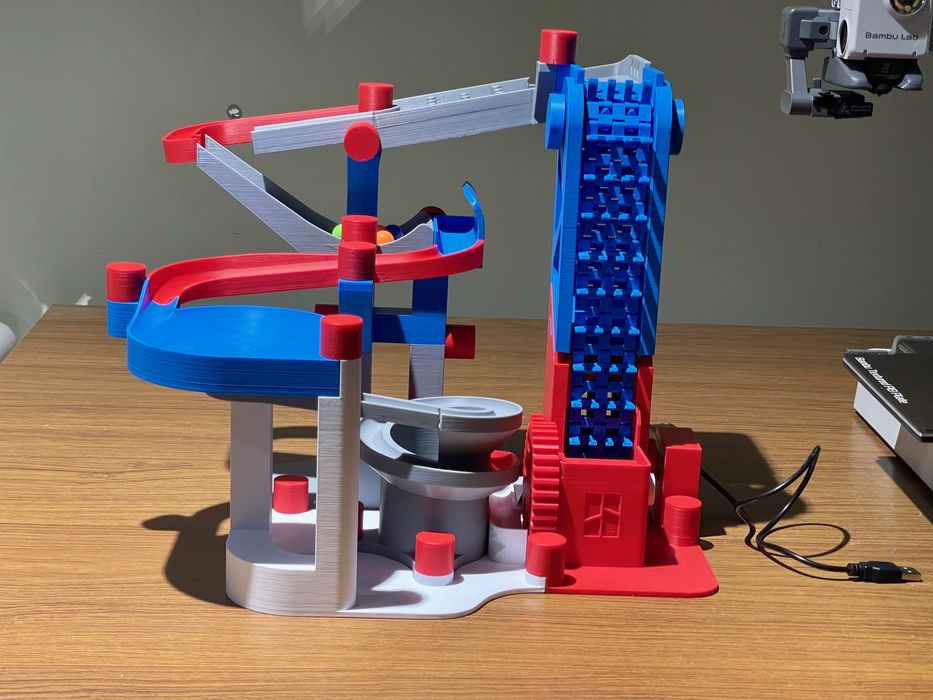

The Marble Run project took a couple of days to print, which was uneventful but long. Assembling the project was fun, and I ended up with this huge machine that drops marbles down a long chute. It’s a bit noisy, but shows how you can produce large items on this relatively small printer.

I tested TPU briefly, and there was no problem at all. The material sticks properly, and there were no jams. The output was near perfect, as usual.

I swapped in the 0.2mm nozzle and tried printing something small. Here we have four figurines ranging from 50mm down to a mere 6mm tall, and it worked about as well as you could expect. There is actually some detail on the smallest figurine. Note #3DBenchy in the back for scale.

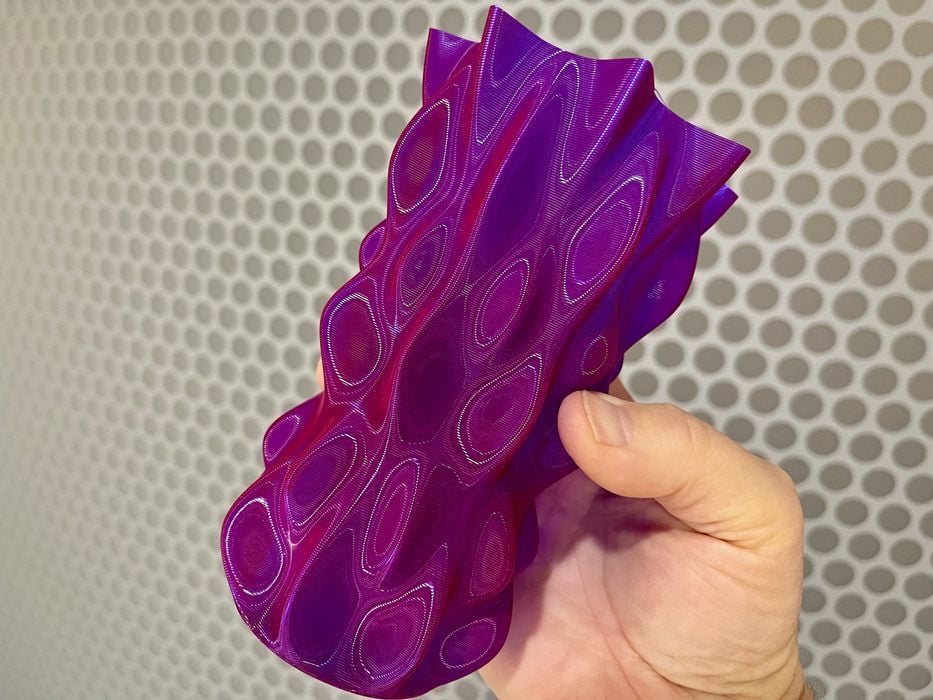

I also tried the 0.8mm nozzle, and found that you could print quite rapidly as more material is deposited each second. I tried printing the Lumpy Bumpy vase, and it turned out far better than I thought.

The 0.8mm nozzle provides much stronger vase mode single walls, ideal for this application. I also found that the reflections on the vase were heightened by the larger extrusions. I made several of these because they were so attractive.

Bambu Lab A1 mini Final Thoughts

Where do I start? The Bambu Lab A1 mini is by far the most impressive desktop 3D printer I’ve ever tested, and it’s not close. This is the first printer we are going to rate as a “10” in over one hundred reviews.

Our process is to identify three best features and three questions. I can tell you there are a lot more than three best features, and it was difficult to find three questions.

The A1 mini is a very fast, reliable and inexpensive desktop 3D printer that produces near-perfect prints every time. It can handle multimaterial prints if equipped with the AMS, which I strongly recommend.

The A1 mini is so compelling I have concerns for other desktop 3D printer manufacturers that now have to match the capabilities of this machine. Bambu Lab has raised the bar, and done so quite significantly.

BAMBU LAB

A1 MINI 3D PRINTER

★ BEGINNER 10/10

★ ENTHUSIAST 9/10

★ PRODUCTION 7/10

BEST FEATURES

✔︎ Reliability

✔︎ Ease of use

✔︎ Speed

QUESTIONS

✖︎ Materials

✖︎ Build volume

This is part four of a four part series, please read parts one, two and three.

Via Bambu Lab

منبع: https://www.fabbaloo.com/news/hands-on-with-the-bambu-lab-a1-mini-part-4